|

|

Most MCUs (microcontrollers) are not equipped with

sufficient RAM space for execution. The common alternatives are all

sub-optimal: either upgrade to a microcontroller with higher density

embedded RAM at a significant premium, or go with an external serial EEPROM

with limited write endurance and serial access. |

|

MCU |

RAID

|

RFID

|

Smart Card

|

SRAM Replacement

|

|

|

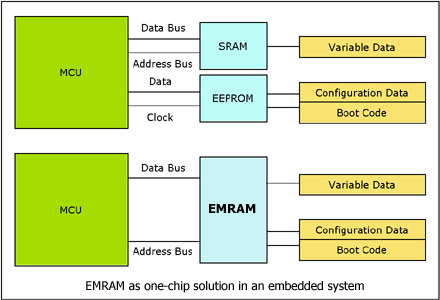

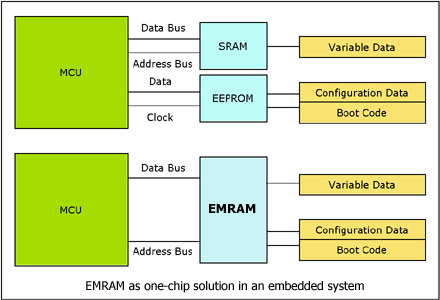

EMRAM Extension of MCU

EMRAM is a fast memory (cycle time <70ns), is nonvolatile and

has unlimited write / read endurance. It is in effect RAM and nonvolatile

storage in the same device. Because of this unique combination, EMRAM is a

perfect choice as the external supplemental memory to a MCU. The user can

decide on the segmentation of volatile and nonvolatile data within a single

EMRAM device. To further optimize the performance of the MCU-EMRAM

combination, the user can assign variables that require high speed and

frequent access to the embedded RAM.

This document outlines some key memory considerations facing

the user today, and how EMRAM can be integrated into the system.

Memory Applications

As a RAM-extension of the MCU, EMRAM can be

used in all of the following memory applications:

Sample Storage

This is the place where the software collects data for later processing.

This is a write intensive application with high data-sample rate that

rapidly accumulates write cycles. In certain applications, data is not

collected at sufficiently high rate because of the bottleneck in memory

speed.

EEPROM is not suitable for data storage because of poor

write endurance (100,000-1,000,000 write cycles), slow write time (~10ms)

and high write power (12V). EMRAM overcomes all this. It has unlimited write

endurance, writes with no delay and consumes little power (write voltage

5V).

In an Analog/Digital conversion, EMRAM easily supports data

sampling at less than 1 µs

interval (1MHz) for continuous operation at 365 days / 24 hours while EEPROM

and other memory alternatives cannot.

Scratchpad Buffer

This is a general purpose memory block that is subject to random write

operations. Endurance over long periods is unpredictable and is therefore a

key consideration. Because write operations is essentially random, the user

do not want to employ a memory with a limited endurance performance. As

EMRAM

has unlimited write endurance, it is well suited to even the most demanding

scratch pad buffer needs.

Circular Buffer

This is a memory block where software uses each memory location in sequence

until it reaches the end of the block before starting at the beginning of

the address range. The write operations normally occur periodically and with

a fixed buffer size. It is therefore the least demanding application in

terms of endurance performance.

Microcontroller Interface

In a system that already employs an external

EEPROM to a MCU, adding EMRAM requires simply a replacement of the EEPROM

with a pin-compatible serial EMRAM with the desired memory density. Write

data to new memory locations as though the serial device is a RAM. When a MCU does not support serial RAM, the user application must move data from

EMRAM to the embedded RAM locations before execution.The user will also have

to modify the system to take advantage of EMRAM’s higher speed by acknowledge

polling and removing any delays.

In a system that does not currently use external EEPROM, the

EMRAM device must be designed in. Because EMRAM is available in both serial

(I2C, Microwire, SPI) and parallel (RAM) formats, it should be compatible

with existing MCU interfaces and direct connection is possible. If software

emulation of the interface is required, the user can obtain the appropriate

software from major MCU vendors who maintain a large library of such

software.

Information

furnished is believed to be accurate and reliable. However, NLSC assumes no

responsibility for the consequences of use of such information nor for any

infringement of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any

patent or patent rights of NLSC. Specifications mentioned in this

publication are subject to change without notice. This publication

supercedes and replaces all information previously supplied. NLSC products

are not authorized for use as critical components in life support devices or

systems without express written approval of NLSC.

© 2004 Northern

Lights Semiconductor Corp – All Rights Reserved

www.nlsemi.com

|

|